- Joined

- 30 Apr 2024

- Messages

- 6

- Reaction score

- 0

- Country

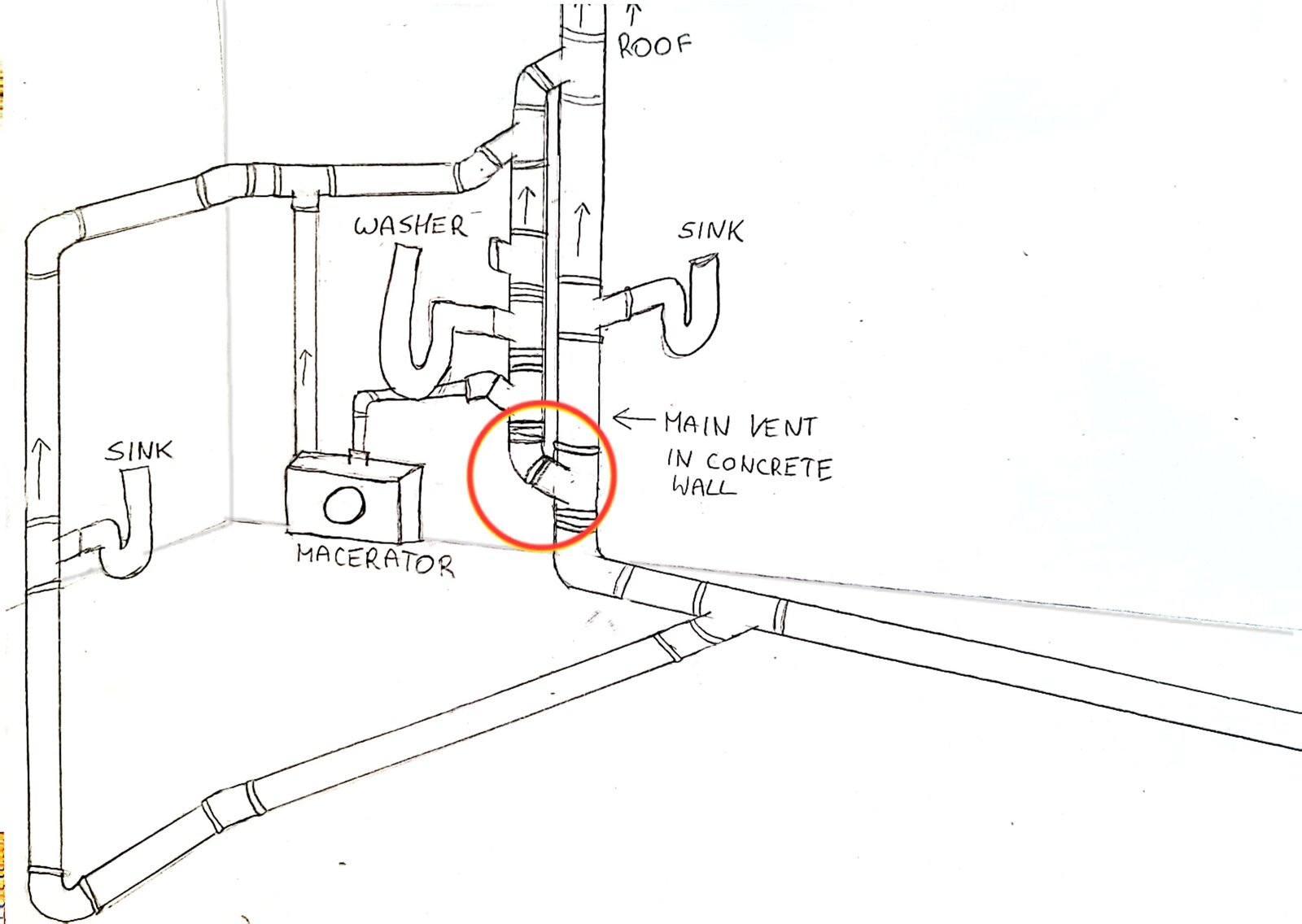

Hi. I am having a bit of an issue adding a fitting in that vertical pipe. It is burried in concrete and there is a copper water line sitting right behind the ABS pipe.

There was an old san-tee in the spot so someone probably patched the hole with concrete. I had to be really careful while cutting the old tee out and removing the cement around it.

Now I am not sure how to fit the wye in there since there is no room to wiggle the ABS so that I could fit the wye to the bottom and add a fernco from the top. Also, I wont be able to slide 2 couplings, from the bottom and fron the top, due to the copper pipe being too close, plus not having enough room from the bottom to slide the fernco before fitting the wye. Can't use a fernco thats soft enough to fold it before fitting the wye and then unfolding it, due to the copper pipe...

Do you know of any tricks to add a tee when an ABS is sitting tight and having little room around it and below?

There was an old san-tee in the spot so someone probably patched the hole with concrete. I had to be really careful while cutting the old tee out and removing the cement around it.

Now I am not sure how to fit the wye in there since there is no room to wiggle the ABS so that I could fit the wye to the bottom and add a fernco from the top. Also, I wont be able to slide 2 couplings, from the bottom and fron the top, due to the copper pipe being too close, plus not having enough room from the bottom to slide the fernco before fitting the wye. Can't use a fernco thats soft enough to fold it before fitting the wye and then unfolding it, due to the copper pipe...

Do you know of any tricks to add a tee when an ABS is sitting tight and having little room around it and below?